5 Common Small Engine Rebuilding Mistakes

The engine is the heart of your garden tractor. When performing heart surgery on your tractor, be aware of the 5 most common mistakes we have identified in our dealings with thousands of customers all over the world.

The following mistakes are easy to forget and dismiss, but they can also lead to premature wear, lack of power and the need to rebuild the engine again in the near future.

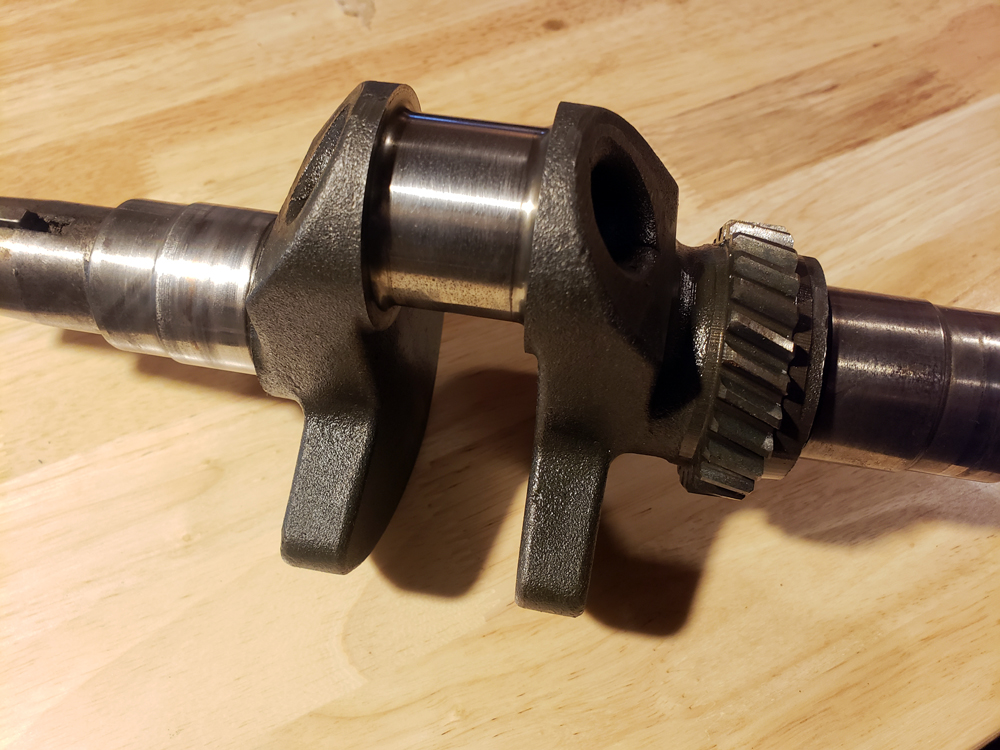

Mistake #1: Not measuring your Cylinder and Crankshaft.

This is probably the most common mistake we encounter. For Kohler K Series engines your cylinder can be out of spec by as little as .003” and your crankshaft can be out of spec by as little as .0005”. We have had many customers determine that they want standard size parts simply by looking at the smoothness of the cylinder bore and the crankshaft. Your eye however is not able to detect a crank journal from being out of round by .0005” (Half a thousandths of an inch) or a cylinder being tapered by .004”. An engine that is out of spec may not neccessarily have any obvious signs of wear or damage.

If you want your rebuild to last as long as possible make sure you measure your bore and crankshaft with a micrometer.

Caption: This crankshaft looks good, right? It is actually .0015" out of round which puts it out of specification for a standard connecting rod.

Mistake #2: Not Measuring with a Micrometer

Calipers are great at many things but not great at measuring engine parts. Any movement of your wrist while measuring will throw your measurement off. It is best to use a micrometer as it is easier to hold perpendicular to the part being measured, and doesn’t move unless you turn the thimble. Using a micrometer takes practice so be sure to practice with known “standards” to fine tune your technique.

Caption: Measuring piston skirt with micrometer

Mistake #3: Not Properly Repairing Valve Seats

If your valve seats are damaged use a valve seat cutter to repair the seat surface. Many people assume valve lapping compound will do the trick, but valve lapping compound does not remove significant enough amount of material to correct damaged valve seats. If you don’t own a valve seat cutter, your local automotive machine shop can do the procedure for you. If you have more than one tractor, you may want to invest in your own valve seat cutting tools.

Caption: Neway Valve Seat Sutter

Mistake #4: Not checking End Gap

It is normal for new piston rings to require some final fitting. Failure to double check your rings’ end gap can lead to the piston seizing in the cylinder afters it has warmed up. Make sure before installing the rings onto your piston to push the rings into the cylinder by themselves and measure the end gap with a feeler gauge. Use a file to widen the gap if needed.

Caption: Carefully filing piston rings to correct end gap.

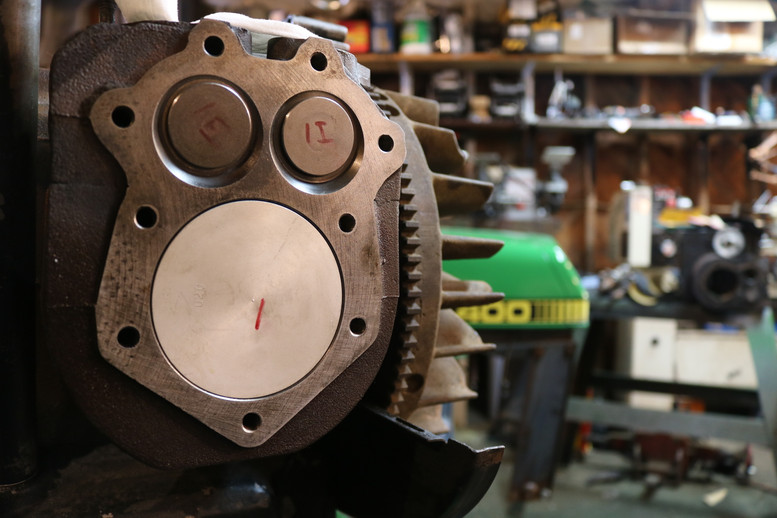

Mistake #5: Not Checking your Cylinder Head for Flatness

The better the seal in your combustion chamber, the more power it will produce. Even if your engine has never blown a head gasket, you should check the flatness of your cylinder head with a feeler gauge and a flat surface. For the flat surface you can use a glass counter top or a granite surface plate. If you can stick a .003” feeler gauge between any of the bolt holes in the head, you should flatten it. You can do this by adhering some medium to fine grit sandpaper to your flat surface, adding water on top, and running your cylinder head back and forth...a few hundred times. It’s easier and faster than it sounds!

Caption: Using a granite surface plate, sand paper, and some water to flatten the cylinder head.

As you’ve read, 3 out of the 5 most common mistakes when rebuilding your vintage small engine involves measuring incorrectly or not measuring at all. If you avoid these mistakes you will have an engine that produces full power, runs smoothly, and will last another 30 years.

We have more tips, instructions, articles, and how to videos on our website, www.isavetractors.com.

Thank you for saving the tractors!

- Norman, iSaveTractors

Recent Posts

-

A Letter From the Owner of iSaveTractors

Dear Friends and Fellow Tractor Enthusiasts, After over a decade of serving the vintage small engine …Jun 5th 2025 -

Rebuild your Old Kohler K Series Engine vs Buying New

Why Rebuilding Your Old Kohler K-Series Engine Beats Buying a New Mower or Engine In today’s t …May 13th 2025 -

iSaveTractors vs Cheap Parts from Amazon

Why iSaveTractors Parts Outshine the Cheap Alternatives on Amazon When it comes to restoring and mai …May 12th 2025