Understanding Your Battery Ignition System on your Kohler K Series Engines

Engine Science: How a Battery Ignition System Works

As Published in July/August Issue of Lawn and Garden Tractor Magazine

By Norman Ng, iSaveTractors.com

I meet a lot of people who are completely comfortable and confident disassembling an entire engine. However some of these same people are intimidated by electrical issues in their tractor. To many tractor enthusiasts, the idea of electricity is mysterious and viewed as if it were magic. A common problem is an engine losing spark. I see many customers when faced with a “no spark condition”, just start replacing parts without an understanding of what each part does and how it relates to the operation of the ignition system.

In this article I give you a brief overview on the major ignition system components and how they work. I hope this gives you a better understanding on how your tractor’s ignition system works so you can better diagnose future ignition problems.

Before I go into the ignition system, let’s first go over some basic electric theory:

Conventional Electric Flow – Electric Current Moves frompositive to negative. In the case of battery ignition systems electric energy will flow from the positive side of the battery through the ignition circuit to the negative side of the battery. Electric current only moves when the circuit is complete from the positive to the negative side of the battery.

Ohm’s Law – Ohm’s law explains the relationship between Amperage, Resistance, and Voltage. It can be illustrated mathematically as Voltage = Amperage times Resistance or V = I x R. By using basic Algebra, you can determine all three values for example: Amperage = Voltage divided by Resistance or I = V/R. Resistance = Voltage divided by Amperage or R = V/I.

In the case of our tractors using battery ignition, we always know our voltage is 12 Volts DC coming from the battery. By using an Ohm meter to gauge resistance of a length or wire or a load, we can determine the amount of current that is used.

Faraday’s Law – Faraday’s Law explains electromagnetic induction when an electromagnetic field suddenly changes.

Battery Ignition System Explained:

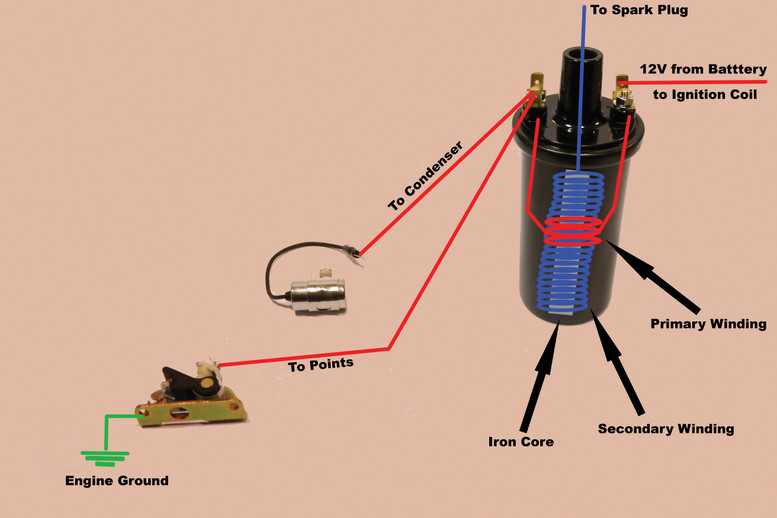

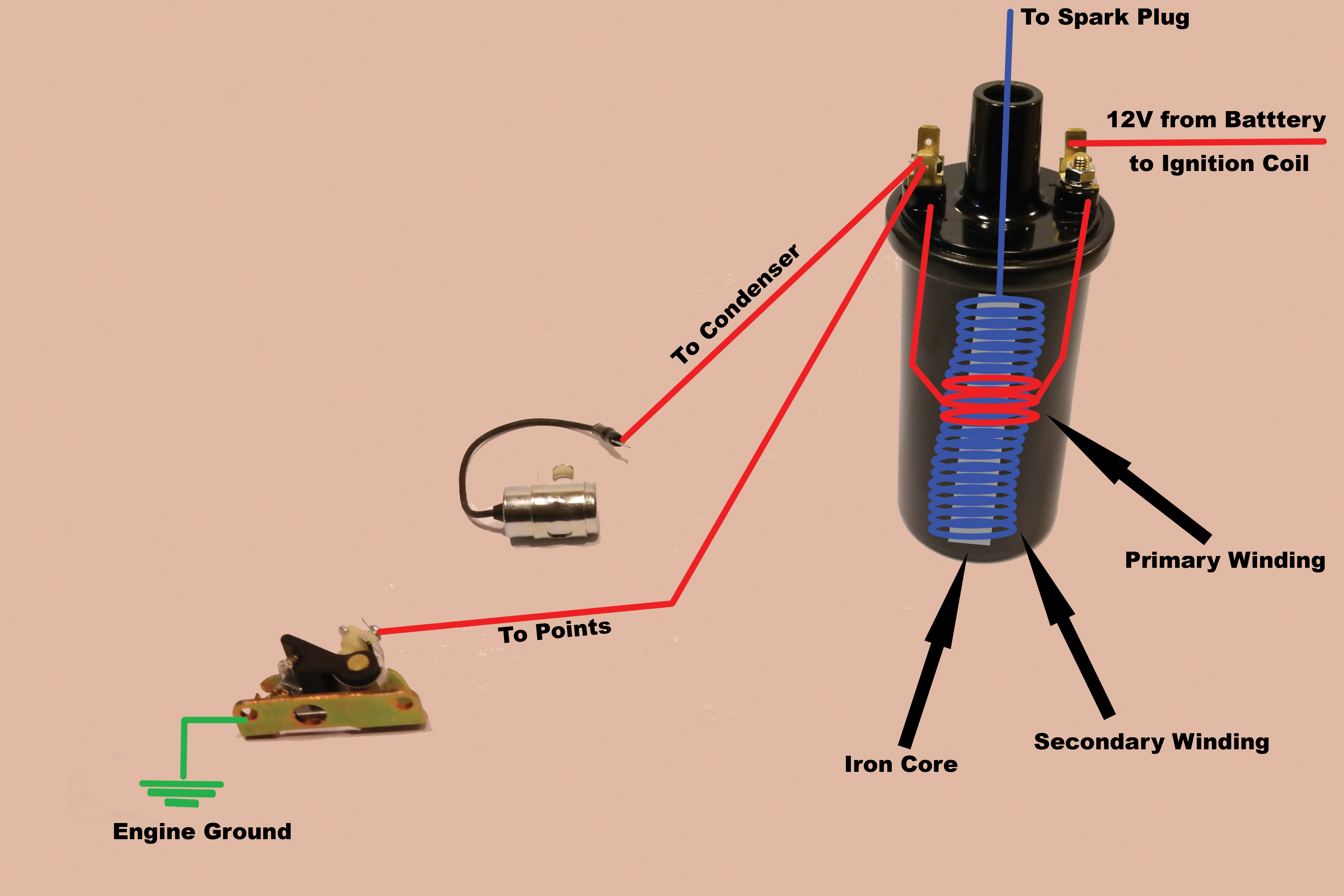

Your engine’s battery ignition system is made up of 5 major components: The battery, ignition coil, points, condenser, and spark plug. Each component plays a vital role in your ignition system.

The battery provides 12 volt electric current to the ignition coil, which generates electromagnetism in the ignition coil.

The ignition coil transforms the 12 volt electric current from the battery into about 20,000 volts. The ignition coil is made up of 3 primary parts: A Primary winding, a secondary winding, and an iron core. Both windings are wrapped around the iron core and are insulated from each other with a special coating. The primary winding is made up of a thick conductive wire with fewer turns. The secondary winding is made up of thin conductive wire with many turns. The whole assembly is inside a metal casing and surrounded with oil to keep everything cool.

The points open to break the electrical circuit in the primary winding and cause a rapid breakdown of the ignition coil’s magnetic field.

The condenser soaks up residual current from the primary windings of the ignition coil.

The spark plug provides a path for the high voltage electric current from the ignition coil’s secondary winding to travel to the common ground and to produce a spark.

How it all works together:

When your engine is on and running: electric current flows from the positive side of the battery through the ignition coil’s primary winding, then through the points and then to the negative side of the battery through a common ground.

During this time an electromagnetic field builds around the iron core inside the ignition coil.

As the engine turns there is a bump on the camshaft that pushes a plunger outward and opens the points.

When the points

open the electric current is suddenly stopped and the magnetic field in the

ignition coil suddenly collapses. This induces an electric current in the

secondary winding. Since the secondary winding is made up of a very long length

of wire, it has a higher resistance than the primary winding. This higher

resistance creates a very high voltage of about 20,000 volts. This high voltage

current travels up to the spark plug where it jumps across the spark plug gap

to reach the common ground. This

“jumping the gap” creates a high energy spark that ignites the air fuel mixture

in your engine.

At the same time, the condenser soaks up a residual electric spike that occurs in the primary winding during collapse of the magnetic field.

All of this happens in a fraction of a second and is repeated every third cycle during your engine’s operation.

In order for this process to work all of the major components: battery, ignition coil, points, condenser, and spark plug need to be in good condition.

The battery is needed to build the electromagnetic field in the ignition coil. The ignition coil is needed to step up the voltage for the spark plug. The points need to connect the battery to the common ground to create the magnetic field in the ignition coil. The condenser needs to absorb the electric spike, and the spark plug needs to provide a path to ground for the high voltage current.

I hope this article helps you understand how your ignition system works and is useful next time you find yourself in a “no spark condition.”

Thank you for saving the tractors,

Norman Ng

Recent Posts

-

A Letter From the Owner of iSaveTractors

Dear Friends and Fellow Tractor Enthusiasts, After over a decade of serving the vintage small engine …Jun 5th 2025 -

Rebuild your Old Kohler K Series Engine vs Buying New

Why Rebuilding Your Old Kohler K-Series Engine Beats Buying a New Mower or Engine In today’s t …May 13th 2025 -

iSaveTractors vs Cheap Parts from Amazon

Why iSaveTractors Parts Outshine the Cheap Alternatives on Amazon When it comes to restoring and mai …May 12th 2025