Preventative Maintenance

Engine Science: Preventative Maintenance by Norman Ng

As published in Lawn and Garden Tractor Magazine March, 2017 Issue

We all know we should take care of our engines in order to maximize their life span. However, many of us are guilty of not doing annual tune ups and oil changes. Some of us may even boast that our engine has been running for 30 years without an oil change!

I guide many people through the small engine rebuild process. After completing a rebuild some customers can’t wait to do it again with another engine, while others ask me what they can do so they never have to rebuild the engine again.

By doing preventative maintenance on your working engines, you can maximize their life, power, and fuel economy.

The goal in preventative maintenance is to make sure your engine continues to burn the proper ratio of air and fuel; sparks at the correct time; and is able to keep itself cool during operation. Neglect in any of these areas will lead to premature engine failure. The good news is it’s simple to keep your engine running in tip top shape.

Change Your Air Filter Often

Air is more important than fuel to your engine. Your engine consumes about 15 parts of air for every part of fuel. Keep the air coming, and keep it clean with fresh air filters. If you use your machine daily, check the air filter weekly and change it when it’s dirty. Don’t use compressed air to clean your air filter. It can puncture the filter element and allow dirt and debris to enter your engine. Dirt and dust can erode your piston and valves very quickly. A clogged air filter can also lead to an overly rich fuel mixture. A rich fuel mixture will leave more carbon deposits in your combustion chamber.

Check Your Ignition Points Yearly

If your engine uses breaker points to control the ignition timing, you need to check the condition of the point contacts every year. As the breaker contacts wear, they can develop pitting, oxidation, and erode. This all affects your ignition quality. You can clean up contact points with a point file, and by rubbing them with plain paper. I however recommend you simply replace the points and condenser every year.

Ignition timing that is too early or too late can greatly impact the performance and life of your engine. If the timing is too early (advanced) the piston and connecting rod will receive additional stress, and your engine will not develop full power. If the timing is too late (retarded) your exhaust valve will get very hot, and your fuel mixture will not burn completely. To prevent this make sure your point gap setting is correct after you service them.

Check and Change Your Oil Often

Your engine’s motor oil is the primary way your engine keeps its internal parts clean and cool during operation. As your engine’s oil goes up and down in temperature it loses some of its chemical attributes over time. Oil also keeps metallic dust and other wear from engine components suspended in the bottom of the oil pan. The only way to get them out is by changing your oil and changing it often. Be sure to also check your oil each time before you start it to make sure no water of gasoline has made its way into your oil pan. Oil that contains other liquids mixed in greatly reduces its cooling and cleaning effectiveness.

Clean Your Air Cooling Fins

Mice, squirrels, and other varmint can make homes inside your engine’s air cooling system. They often build nests in between your flywheel and shroud. These nests can block the air flow around your engine’s block preventing it from cooling properly. A hot engine will wear faster, and operate less efficiently.

Clean the Combustion Chamber

Remove the cylinder head from your engine and clean the carbon build-up on your piston, valves, and cylinder head. This is also a good time to inspect the piston, cylinder, head, valves, and valve seats for any wear. Depending on how often and how hard you work your machine, you should do this anywhere from every year to every few years. Combustion chamber deposit build-up can prevent your valves, and rings from seating properly.

Keep Your Fuel in Check

Ethanol in gas is not the only enemy of old engines. Condensation, moisture, and dirt can also collect in your fuel tanks, carburetor, and fuel lines. You can keep these out of your engine by using proper in-line fuel filters and treat your fuel with a marine fuel treatment stabilizer, such as Marine Sta-Bil.

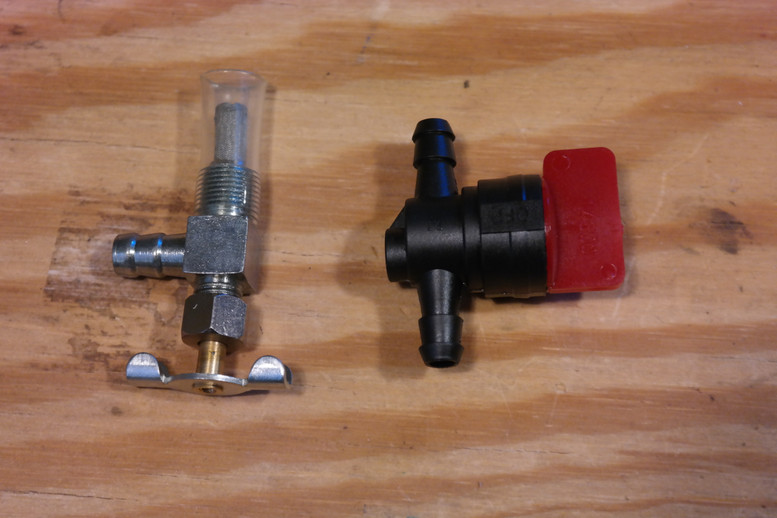

It’s also a good practice to install a tank or in-line fuel shut off valve if your engine’s fuel is gravity-fed. This precaution will prevent fuel from flooding into your engine when stored for long periods of time.

By following these 6 simple steps you can keep your newly rebuilt engine running strong for a very long time.

Thank you for saving the tractors!

Recent Posts

-

Engine Science: Rewind Your Small Tractor Engine Stator - Charging System Repair

Engine Science: How to Rewind Your Statorby Norman Ng, Founder of iSaveTractorsYour engine’s stator …Sep 10th 2020 -

Engine Science: The Digital Multi-Meter

The ability to detect, observe, and measure electricity is crucial when trying to understand how a …May 7th 2019 -

5 Common Small Engine Rebuilding Mistakes

The engine is the heart of your garden tractor. When performing heart surgery on your tractor, be aw …Jan 4th 2019