Tractor Science: Hydraulics

Do you want to turn your old garden tractor into a serious earth moving machine? How about convert your manual lift system into a power system? Want to add a rear PTO? Do you want to multiply your engine’s power by 1,000 times or more? It’s all possible by using the science behind hydraulic power!

A hydraulic system is a simple, space efficient way of multiplying and transferring your engine’s power to multiple applications for your tractor. By utilizing hydraulics you can build a front end loader, backhoe, 3 point hitch, 3 way plow, a dump trailer and much more. The limits are in your imagination.

In this article I am going to go over the basics of hydraulics and how you can take advantage of the physics of fluid.

Basic Hydraulic Principles

The 3 Most basic principles behind hydraulics are:

1.) Liquids are incompressible

2.) Liquids transmit pressure in all directions and with equal force at right angles to all surfaces

3.) Liquids under pressure follow the path of least resistance

Some Hydraulic Terms to Know

Pressure: Is the resistance to flow normally created by a load. This is expressed as Pounds per square inch or PSI

Flow: This is the rate of which fluid flows through a system. This is expressed as Gallons per Minute or GPM

Displacement: This is the volume of fluid.

Basic Components of a Hydraulic System

The basic components in a hydraulic system are:

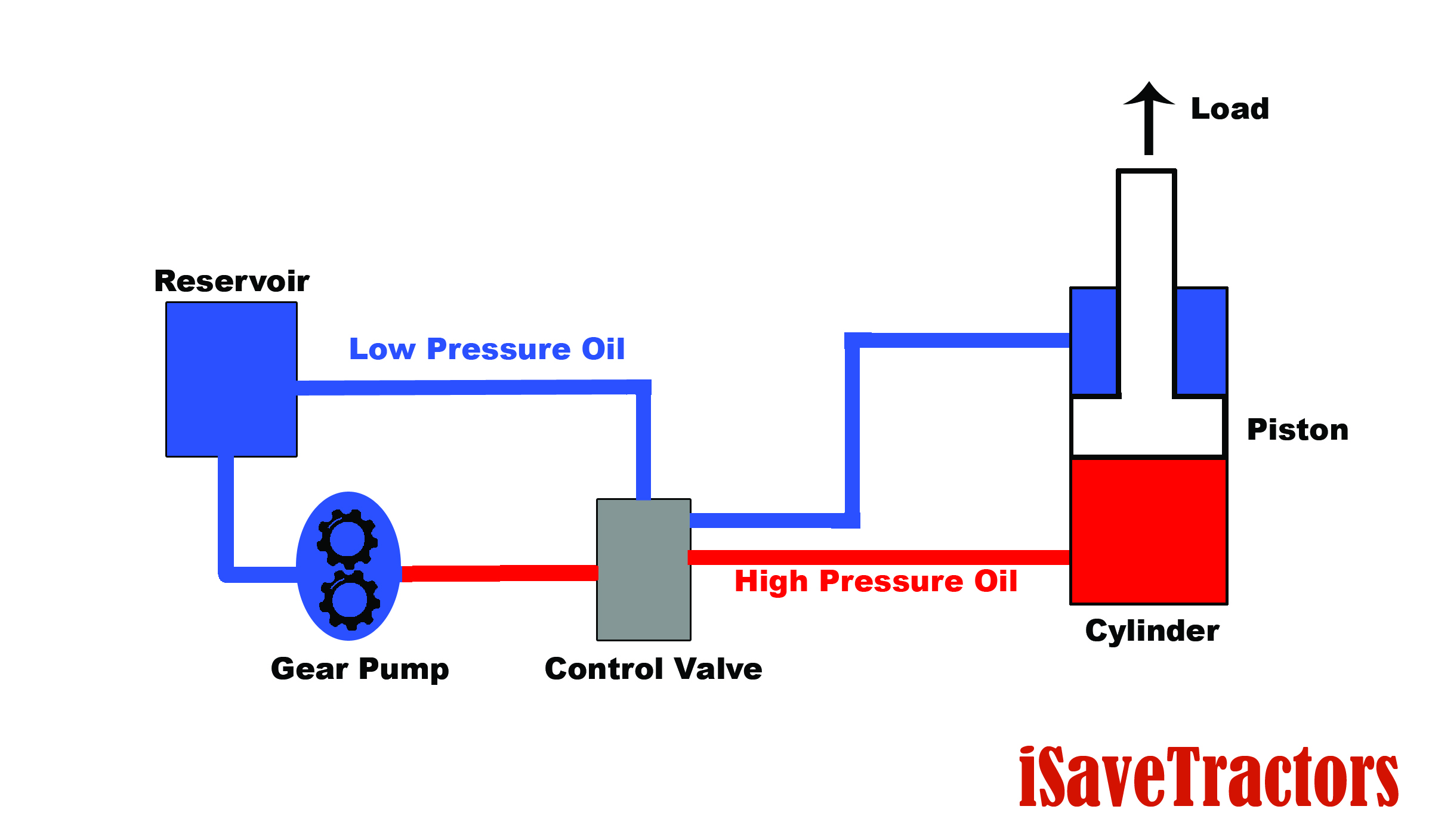

1.) Reservoir 2.) Pump 3.) Valve 4.) Piston or Motor

The reservoir holds the fluid; in the case of our garden tractors, oil. The pump moves oil throughout the entire system. The valve directs oil to different hydraulic cylinders or motors. The Piston or Motor is where the final work is performed. A piston will move loads up and down, and a motor will rotate. All of the components are connected by hydraulic hoses or lines.

How the Hydraulic System Works

The hydraulic system begins with the reservoir. This reservoir contains the oil used in the system. Oil is delivered from the reservoir to the hydraulic pump. From there the oil flows to the hydraulic control valve. Once activated, the valve will allow oil to flow to and from the hydraulic cylinder. At the same time, oil is moved from the cylinder back to the reservoir where the cycle repeats.

How a Hydraulic System Multiplies and Exerts Force

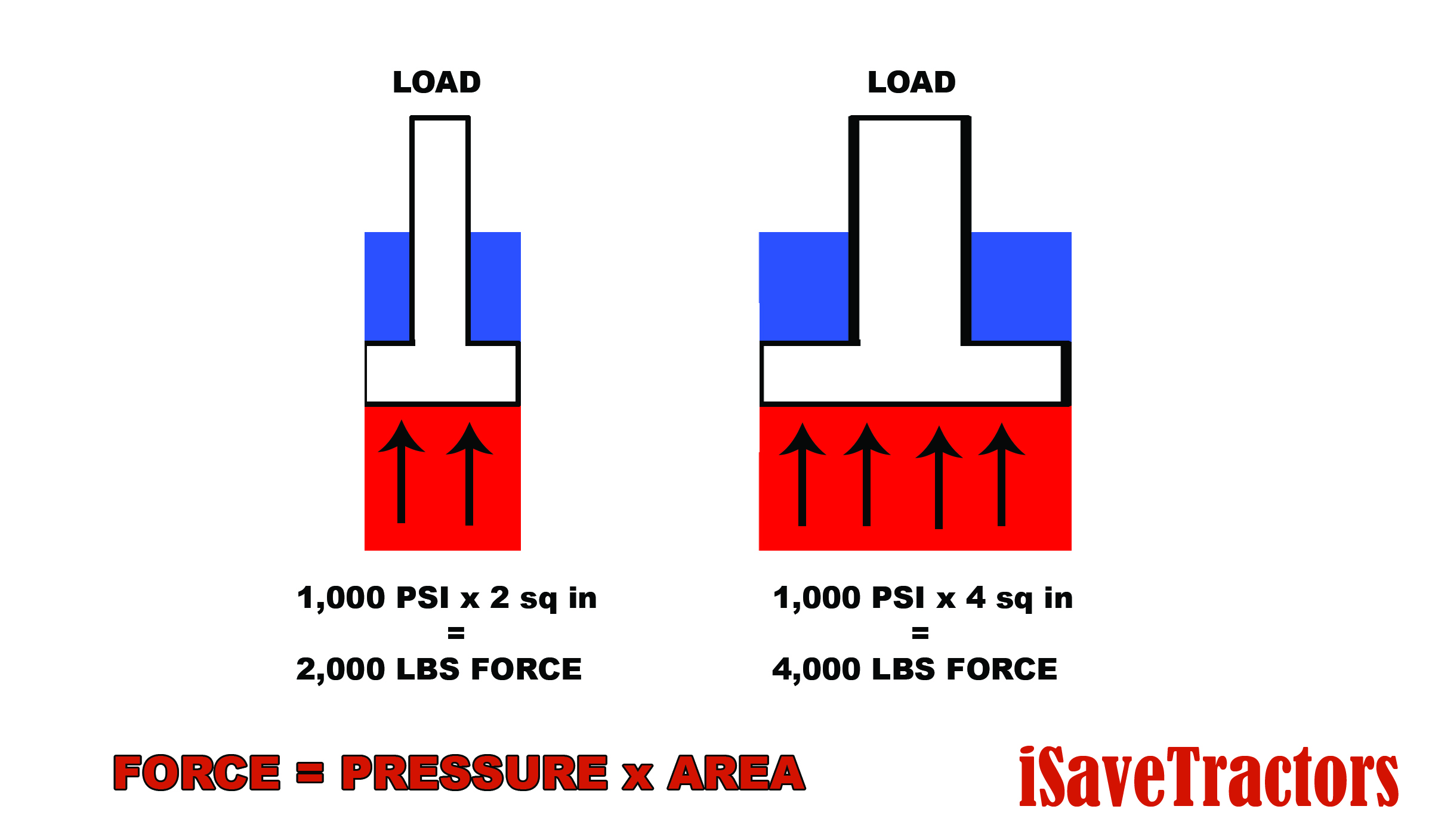

Since liquids exert force equally in all directions we can multiply the force it gives by increasing the surface area in which we want the liquid to push against. Typically we apply this principle in a hydraulic cylinder. The greater the surface area at the end of the cylinder, the more force gets exerted on the moving piston.

This can be illustrated with this math formula: Force = Pressure x Area

So if we were to push liquid at 1,000 psi into a cylinder with an end area of 2 square inches we would produce 2,000 pounds of force. If we were to enlarge the end area by using a larger diameter hydraulic cylinder with a 4 square inch end area, we would produce 4,000 pounds of force. Since the displacement of the larger cylinder will be greater, our cylinder will move slower but with greater force. Like all other forms of mechanical advantage, we trade speed for power.

Applying Hydraulics to your Vintage Garden Tractor

The engines in our beloved garden tractors have enough power to push hydraulic oil to 2,000 psi or more. By pushing this oil into different sized hydraulic cylinders we can build almost any tool imaginable.

In 2015 I built a Front end Loader and a backhoe for a 1974 International Harvester Cub Cadet 149. I built the reservoir into one of the loader towers, and ran an 8 GPM gear pump off of the engine’s front PTO Shaft. This pump was connected to a 2 spool directional control valve with a power beyond port. This power beyond port supplied oil to a 6 spool control valve that controlled the backhoe. My hydraulic system is set to have a maximum pressure of 1,000 psi.

This same principle can be applied if you wanted to build a rear fork lift, 3-point hitch, snow blade set up. Anything! Instead of using a hydraulic cylinder you can use a hydraulic motor and add a PTO shaft to power implements at any location you desire. You can also vary the motor speed by controlling the volume of oil that feeds it. All you need are the 4 basic hydraulic components of reservoir, pump, valve, and device.

This article serves as a basic introduction to what is possible with hydraulics for your garden tractor. There are a wide variety of pumps, valves, motors, hoses, etc. I hope this article inspires you to research more of what you can do with the physics of fluid.

Thank you for saving the tractors!

- -Norman Ng, iSaveTractors.com

Recent Posts

-

A Letter From the Owner of iSaveTractors

Dear Friends and Fellow Tractor Enthusiasts, After over a decade of serving the vintage small engine …Jun 5th 2025 -

Rebuild your Old Kohler K Series Engine vs Buying New

Why Rebuilding Your Old Kohler K-Series Engine Beats Buying a New Mower or Engine In today’s throwaw …May 13th 2025 -

iSaveTractors vs Cheap Parts from Amazon

Why iSaveTractors Parts Outshine the Cheap Alternatives on Amazon When it comes to restoring and mai …May 12th 2025