Engine Science: The Governor System

Engine Science: The Governor System

The governor system in your engine is crucial to keeping your engine running while you enjoy your garden tractor. It’s like cruise control for your engine’s RPMs (rotations per minute). It keeps your machine working regardless if you go uphill, go downhill, hit a thick patch of grass, or pull a heavy load.

There are three types of governor systems used in outdoor power equipment: mechanical, air vane, and electronic. However, for this article, we are going to focus on the system most commonly found in old lawn and garden tractors: the mechanical governor system.

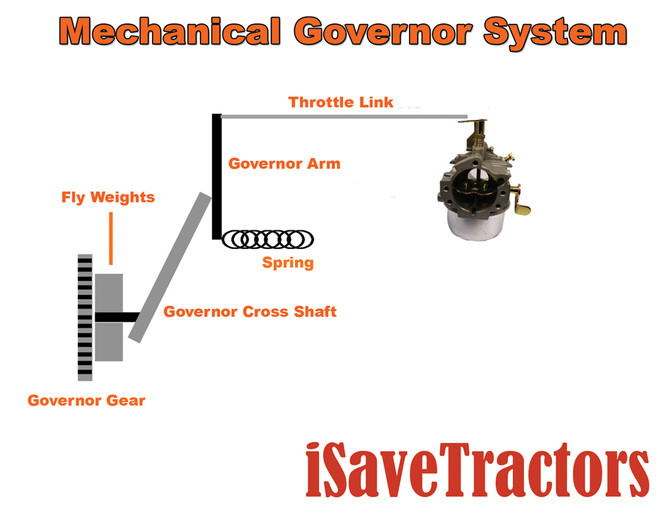

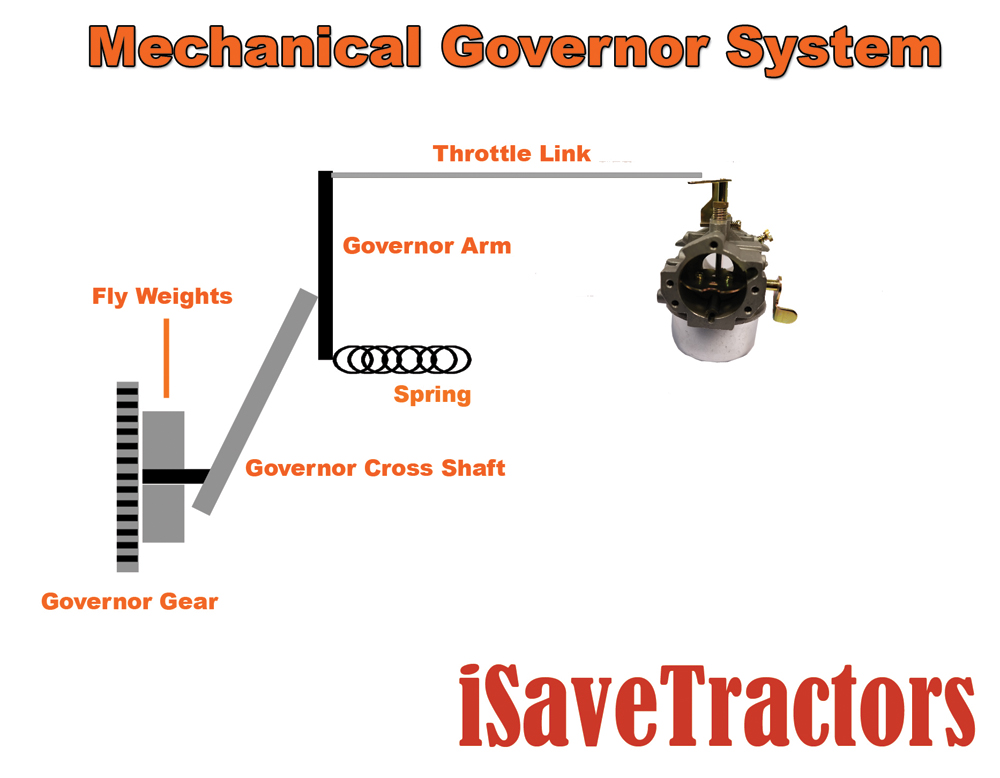

The mechanical governor system utilizes a combination of centrifugal force, leverage, and spring tension to moderate the throttle on your carburetor in order to maintain a consistent RPM regardless of the loads applied against the engine.

Let’s examine the different parts of the mechanical governor system and see how they work to maintain engine RPM.

Your mechanical governor consists of the following parts:

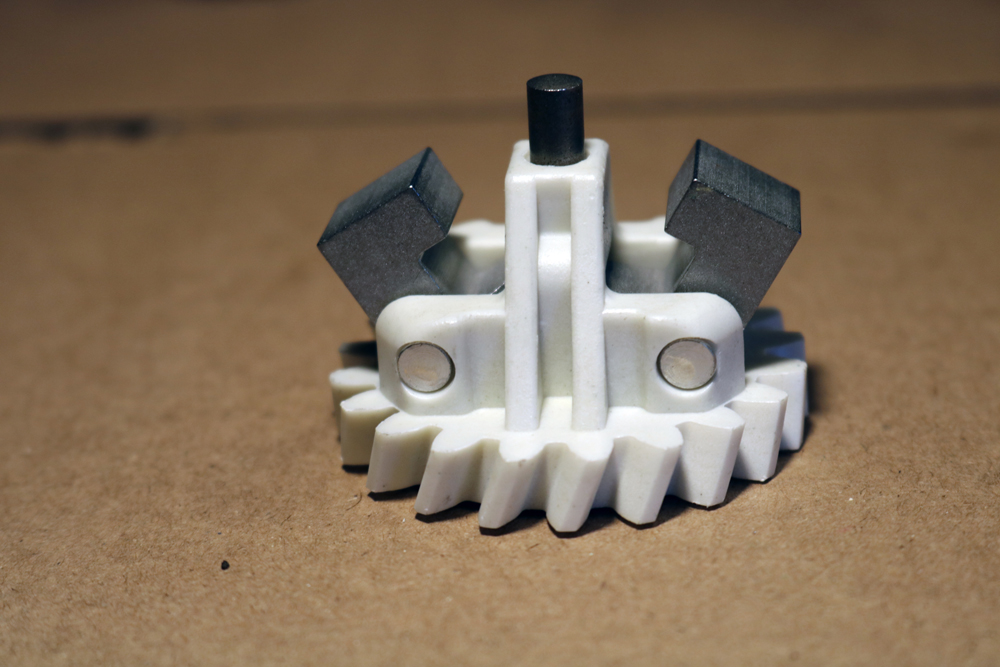

- Governor Gear – The governor gear typically consists of a gear and a set of fly weights that pivot in and out. The governor gear is meshed with the crankshaft, and, as the crankshaft turns, the centrifugal force of the spinning motion forces the fly weights outward. Governor gears are normally inside a small engine’s block, but there are some engines, such as the Kohler K532, that have the governor gear as an external assembly which is bolted to the engine.

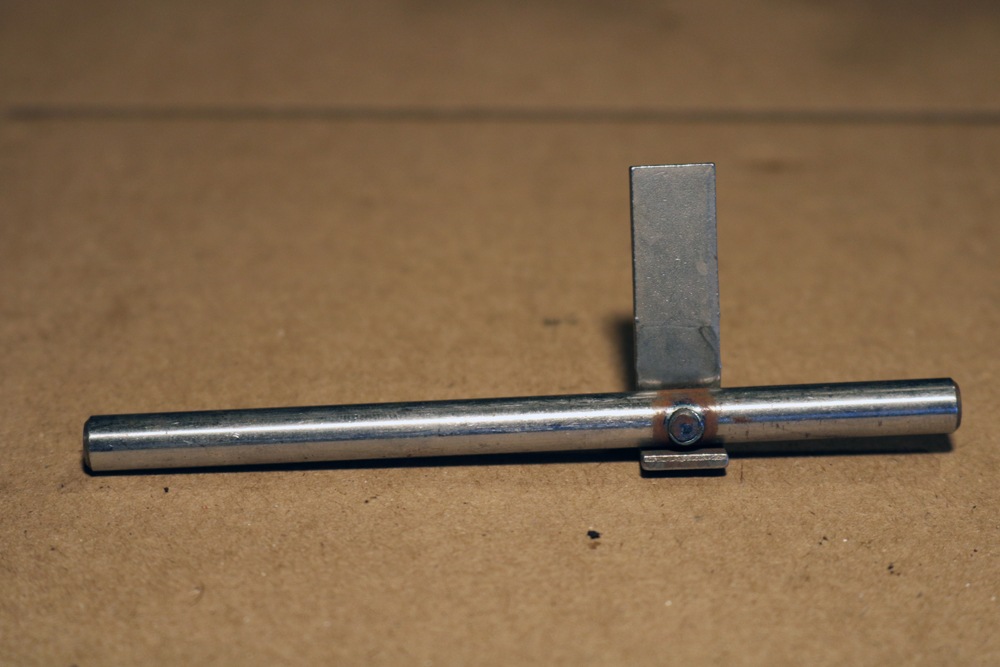

- Governor Cross Shaft – The governor cross shaft is a shaft that connects the governor gear to the governor arm located on the outside of the engine. The governor cross shaft has a tab that presses against the governor gear fly weights.

- Governor Arm – The governor arm is attached directly to the governor cross shaft. One end of the governor arm connects to the throttle linkage, and the other end is connected to a governor spring.

- Governor Spring – The governor spring is attached from one end of the governor arm and to the throttle control of the machine.

- Throttle Linkage – The throttle linkage connects the top of the governor arm to the throttle of your carburetor

How the parts work together to maintain engine RPM

There are two things to keep in mind when thinking about your mechanical governor system:

- The governor gear is always trying to close the carburetor throttle.

- The governor spring is always trying to open your carburetor throttle.

- This tug of war between the governor spring and governor gear is constantly happening as you operate your machine. When the force of the governor gear is equal to the force of the governor spring, your engine’s RPMs are maintained at a constant speed.

As your engine runs, the governor gear is constantly spinning and forcing the fly weights outward. This, in turn, pushes on the tab of the governor cross shaft. The governor cross shaft is forced to rotate and moves the governor arm toward your carburetor to close the throttle. As the throttle closes, the RPMs slow. The governor spring, on the other hand, is always applying tension to the other end of the governor arm which is pulling the throttle open. As the throttle opens, your RPMs speed up. When the two opposing forces—centrifugal force and spring tension—are equal to each other a constant RPM is achieved.

When your engine has a sudden load applied to it, such as when you engage your mower deck, the engine RPM will slow for a moment. As the engine slows down, the fly weights on the governor gear retract, which lowers the centrifugal force applied to the governor arm. This absence of force allows the governor spring’s tension to overcome the governor force, which pulls the throttle open, delivering more air/fuel to increase RPMS.

Tuning the Governor System

You can change how sensitive the mechanical governor system responds to loads by changing the amount of leverage your governor spring applies to the governor arm. The pivot point is where the governor arm meets the governor cross shaft. Below the pivot point there are a series of holes for the governor spring to attach to. The further away from the pivot point your spring is attached, the higher amount of leverage the spring has to apply. This makes it so the governor gear has to overcome a greater amount of force to close the throttle. This effectively makes your governor response less sensitive. On the other hand, if you move your governor spring closer to the governor arm pivot point, it decreases the amount of leverage the governor spring has and thus allows the governor gear to close the throttle with less force. This effectively increases the governor system sensitivity.

Governor Trouble Shooting

Hunting is when your engine quickly changes RPMs on its own. Surging is when your engine slowly changes RPMs when you don’t want it to.

The first step to figuring out your governor problems is to isolate the issue to the governor system. Bound linkages and fuel system problems can mislead you to believe there is a mechanical governor system issue.

Here are some common issues related with mechanical governors and how to fix them:

- -Static Governor Adjustment. Engines that use a separate cross shaft and governor arm, such as the Kohler K Series, need to have he cross shaft and governor arm synchronized in order to work properly. To perform this procedure, begin by loosening the governor arm from the governor cross shaft. Then, using a set of pliers, rotate the governor cross shaft counterclockwise as far as it will go. This pushes the cross shaft against the fly weights of the governor gear. Now, take your governor arm and also turn it counterclockwise as far as it will go to open the throttle to wide open throttle (WOT). Tighten the governor arm, and you’re done. This procedure lines up what’s happening to the governor inside your engine with what’s happening to the carburetor on the outside of your engine.

- -Hunting and surging can be caused by incorrect spring sensitivity and can be resolved by adjusting the governor spring location.

- -If your engine is running erratically even after a static governor adjustment, your cross shaft may need to be examined. The tab on the cross shaft can break after many years of use. If this is your case, the cross shaft will need to be replaced.

I hope this article helps you understand how the mechanical governor system in your tractor’s engine works. In turn, I hope it helps you solve your engine’s RPM problems. If you need any further assistance, feel free to call us at 207-298-9701. You can also see many videos on tractor repair, restoration, and fun projects on our website as well as on our popular YouTube channel.

Thank you for saving the tractors!

Recent Posts

-

A Letter From the Owner of iSaveTractors

Dear Friends and Fellow Tractor Enthusiasts, After over a decade of serving the vintage small engine …Jun 5th 2025 -

Rebuild your Old Kohler K Series Engine vs Buying New

Why Rebuilding Your Old Kohler K-Series Engine Beats Buying a New Mower or Engine In today’s throwaw …May 13th 2025 -

iSaveTractors vs Cheap Parts from Amazon

Why iSaveTractors Parts Outshine the Cheap Alternatives on Amazon When it comes to restoring and mai …May 12th 2025