Engine Science: Measuring Your Engine’s Cylinder Bore

Engine Science: Measuring Your Engine’s Cylinder Bore

By Norman Ng

So you have decided to finally pull apart the engine on your old Garden Tractor and are planning to rebuild as a winter project.

Before you order parts or contact a machine shop make sure you measure your engine components carefully and determine the correct size.

In this article I will explain how to measure your engine’s cylinder bore with a micrometer and a telescoping bore gauge.

The Telescoping Bore Gauge:

The telescoping bore gauge is an inexpensive and accurate way of transferring the dimensions of a bore so it can be measured with another instrument.

The telescoping bore gauge consists of a handle, a tightening screw, and two spring loaded plungers with convex faces.

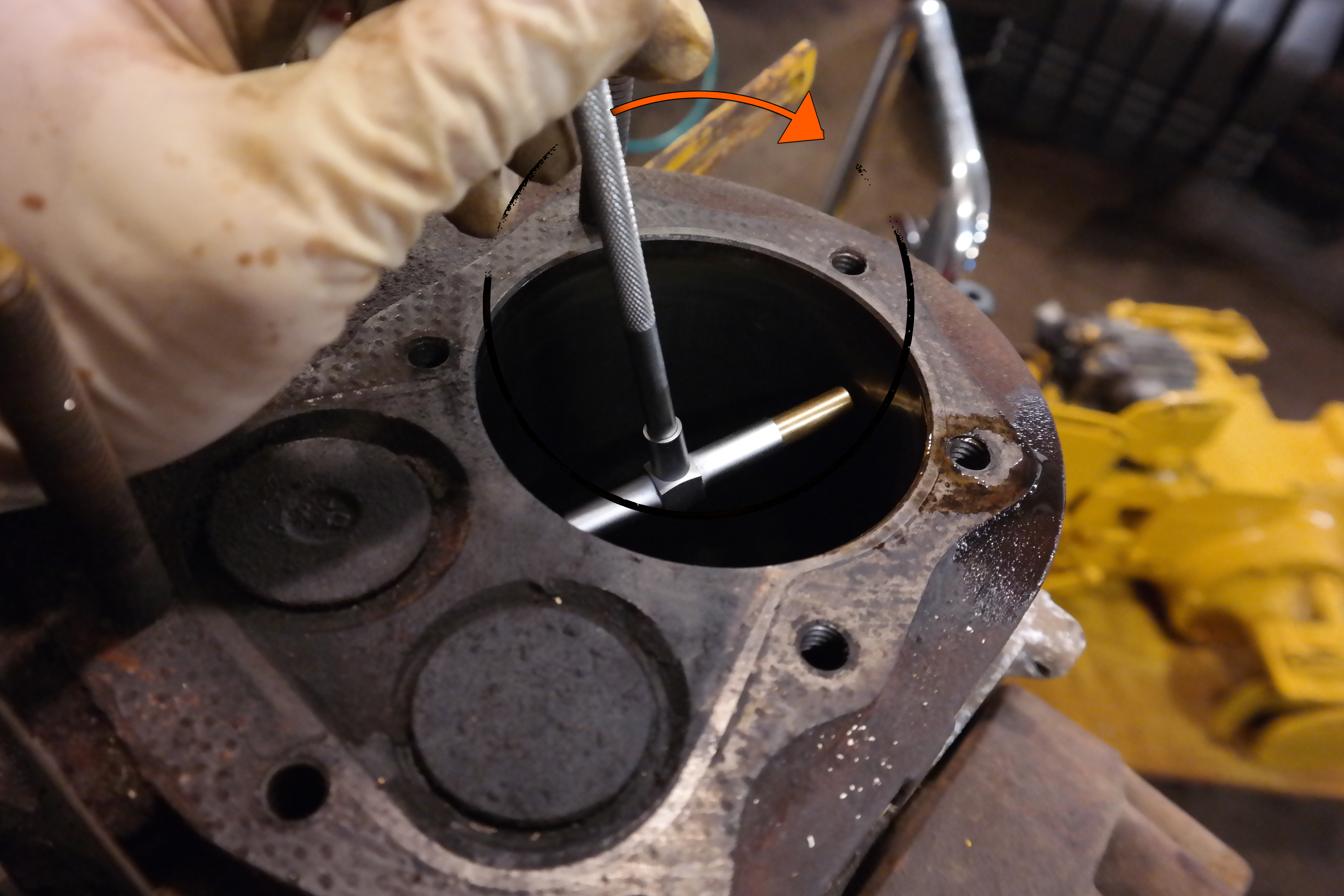

The tightening screw located on the end of the handle allows for the plungers to hold a position when compressed. The convex faces of the plungers play an important role. It allows the plungers to be compressed to the exact size of the bore when the tool is rotated in an arc. See photo below.

The Micrometer:

The micrometer is a precision measuring instrument where each turn of the thimble moves a spindle in and out. The markings displayed on the barrel and thimble are then added together to give you the final measurement. The increments commonly found on a micrometer are illustrated in the photo below.

Measuring Your Cylinder Bore:

When measuring your cylinder bore, we are looking to determine three things:

1. Overall Size

2. Out of Round

3. Taper

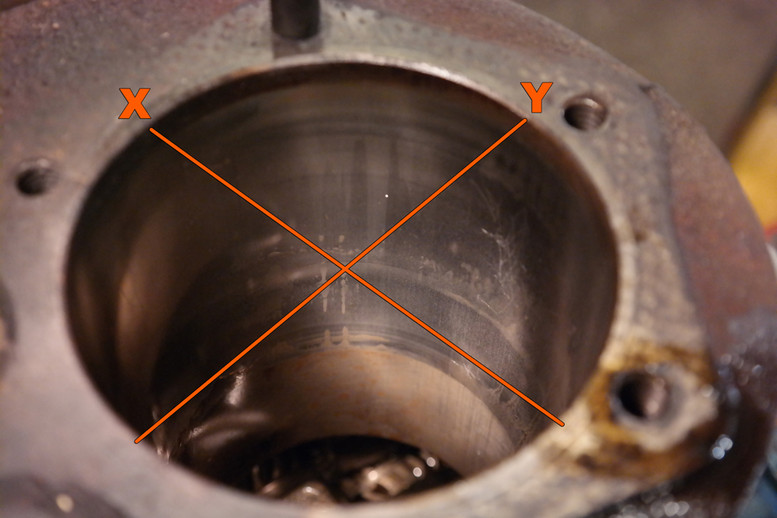

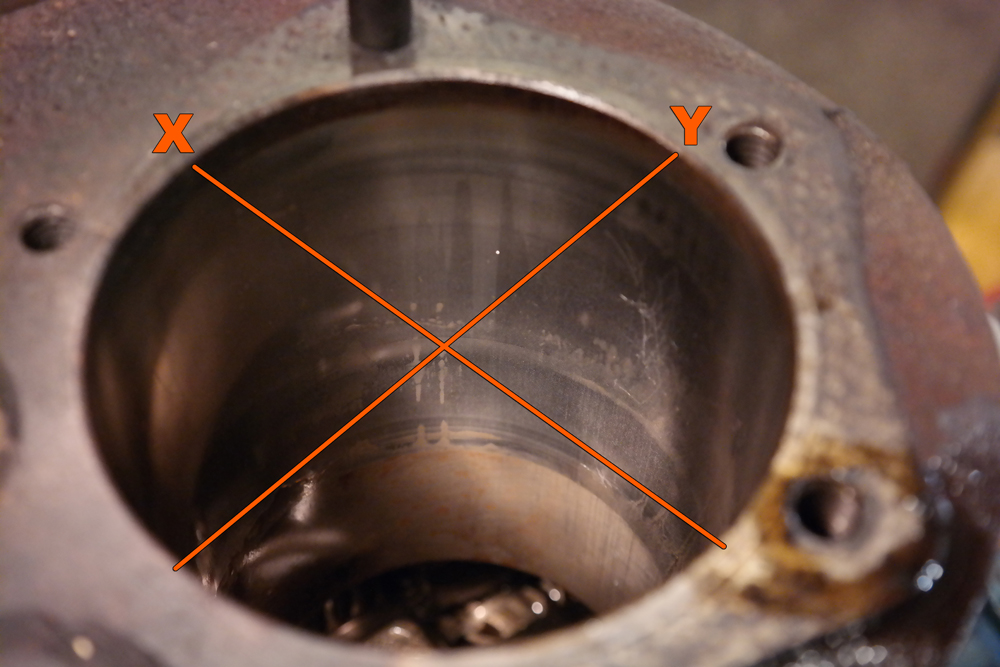

In order to determine this we need to take a total of six measurements. We need to take three measurements along an “X” axis and three measurements along a “Y” axis. We also need to take these measurements at three different depths into the cylinder bore, the top, middle and bottom.

| Depth | X | Y |

| Top | ||

| Middle | ||

| Bottom |

See Photo

To use the telescoping bore gauge:

- 1.Insert the tool into the cylinder bore, and release tension on the tightening screw to allow the plungers to expand.

- 2.Position the gauge so the handle is tilted slightly. This allows the low portion of the plungers’ convex faces to contact the sides of the cylinder bore. Now gently tighten the tightening screw.

- 3.Now in a fluid motion rotate the gauge’s handle in an arc. This motion brings the high point of the convex faces into contact with the cylinder bore. Now carefully remove the tool and tighten the tightening screw a little more to lock in the plungers.

Measuring the bore gauge:

- 1.Secure the frame of the micrometer in a vise. (See photo vise.jpg)

- 2.Hold the bore gauge in between the anvil and spindle of the micrometer

- 3.Turn the thimble so the spindle moves towards the gauge faces

- 4.Keep turning the thimble until the two measuring faces contact the convex faces of the bore gauge. Make sure to keep the highest point of the convex faces in contact with the micrometer.

- 5.When you feel a slight resistance in the micrometer thimble, stop and read your measurement. You want don’t want to turn the thimble too tight nor keep it too loose. A slight amount of pressure is what is needed to take an accurate measurement. If your micrometer has a torque limiter on the end of the thimble, you can turn that until the thimble stops moving. The limiter prevents you from over tightening the thimble.

Repeat this process for all 6 measurements and record your readings.

To determine your engine’s out of round, you are going to take the your measurements from “X” and subtract them from “Y”. Compare these values to your engine manufacturer’s specifications.

X – Y = Out of Round

To determine your engine’s taper, take your measurement from the bottom depth and subtract it from your measurement from the very top of the cylinder. Compare these values to your engine manufacturer’s specifications.

Top - Bottom = Taper

Your cylinder’s overall size is simply your largest single measurement.

I hope this article helps you understand how to measure your engine’s cylinder bore and how to use the tools needed for the job. By having accurate measurements you can be confident that your rebuilt engine will last another 40 years.

Thank you for saving the tractors,

- -Norman Ng

Recent Posts

-

A Letter From the Owner of iSaveTractors

Dear Friends and Fellow Tractor Enthusiasts, After over a decade of serving the vintage small engine …Jun 5th 2025 -

Rebuild your Old Kohler K Series Engine vs Buying New

Why Rebuilding Your Old Kohler K-Series Engine Beats Buying a New Mower or Engine In today’s throwaw …May 13th 2025 -

iSaveTractors vs Cheap Parts from Amazon

Why iSaveTractors Parts Outshine the Cheap Alternatives on Amazon When it comes to restoring and mai …May 12th 2025