Tractor Science: The Hydrostatic Transmission

Tractor Science: The Hydrostatic Transmission

By Norman Ng

The transmission allows an engine’s power to be multiplied and manipulated to drive your tractor forward and backward. It’s an amazing device that makes your tractor a tractor. This article is focused on a specific type of transmission: The Hydrostatic Transmission. We are going to use the Sundstrand Series 15 Type U as an example. This transmission was used on the Cub Cadet line of Garden tractors as well as many other tractors and vehicles.

The hydrostatic transmission allows a tractor to convert mechanical energy into hydraulic power and then back to mechanical energy. This allows us to infinitely change the variation of forward and reverse speed, and makes our transmission unit smaller without sacrificing power. Let’s take a look at the science behind what makes a hydrostatic transmission work.

The Principles Behind Hydraulic Power:

To understand how a Hydrostatic Transmission works we need to first understand the basic characteristics of liquids:

- Liquids cannot be compressed

- Liquids have no shape

- Liquids transmit pressure in all directions and have equal force to all perpendicular surfaces

The hydrostatic transmission moves oil in a closed circuit to rotate a motor in both directions. Because liquids have no shape we can manipulate and route it easily. Since they cannot be compressed and transmit equal force to all perpendicular surfaces, we can use it to multiply input force and transform it into a greater output force.

The speed of your transmission’s output is dependent on the rate of volume the oil is flowing. This is measured in gallons per minute (GPM).

The direction of your transmission’s output is dependent on which direction the oil is being pumped.

The power of your transmission’s output is dependent on the oil’s pressure.

So the faster the oil is pumped from one side of the transmission to the other, the faster your tractor moves, and the higher the pressure, the stronger it turns.

The Advantages of a Hydrostatic Transmission are:

- Ease of use. There are no levers to shift, no clutches to depress. Just move one control lever and that’s it.

- Infinitely variable. You can change have any variation of forward speed between 0 and Full.

- Compact size. Since there is no dependence on gear sets to multiply torque or change directions, the transmission is much smaller.

- A hydrostatic transmission applies torque smoothly and efficiently.

Here are the key components to a Hydrostatic Transmission

Transmission Case

The case holds all of components in place and has passageways to move oil from the pump to motor and back again in a closed circuit.

Charge Pump

The charge pump provides initial case oil pressure and fills the case and circuits with oil. The charge pump also provides oil flow for auxiliary hydraulic ports.

Input Shaft

The input shaft takes power from the engine and rotates the charge pump and the axial piston pump in the transmission.

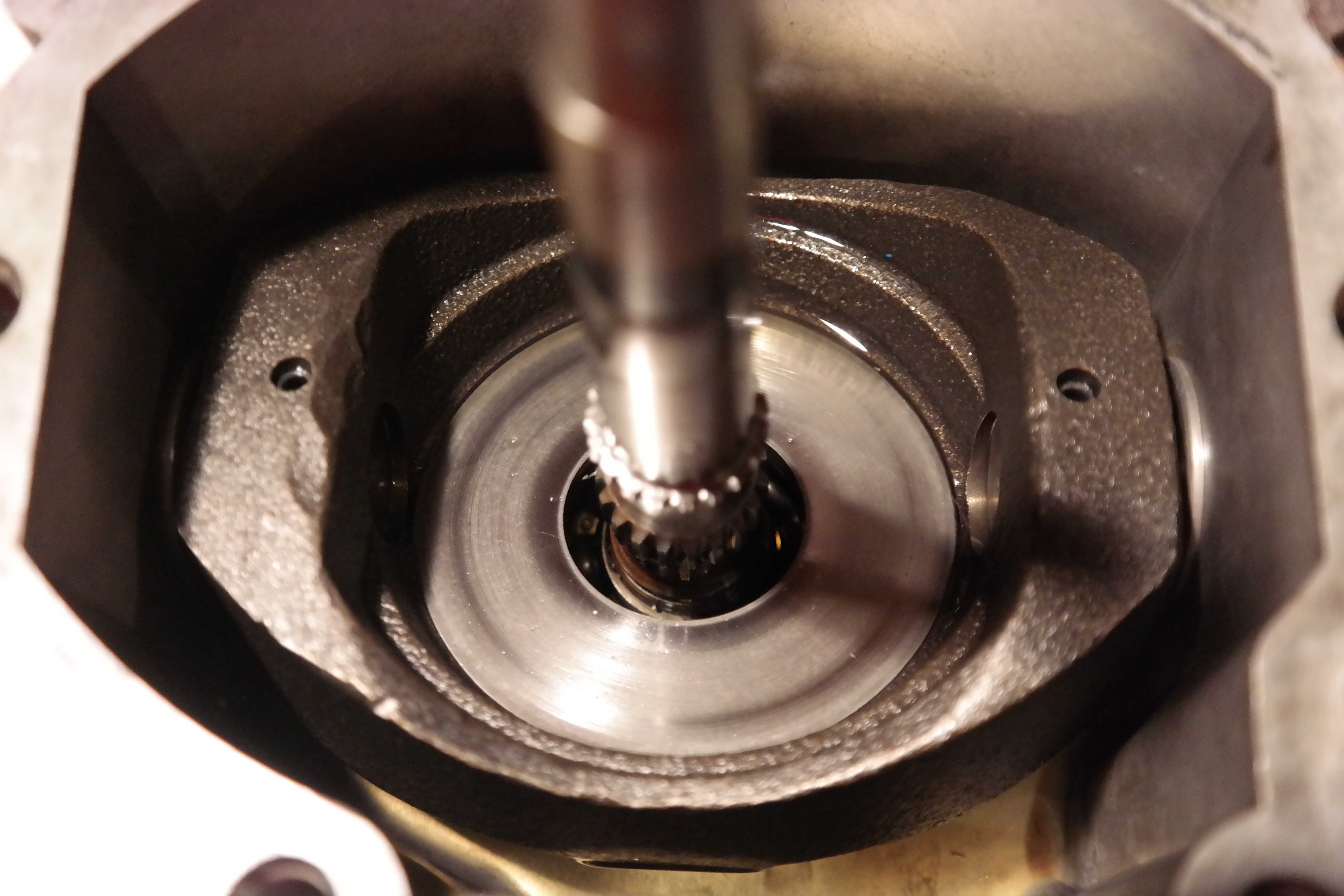

Axial Piston Pump

This pump is the heart of your hydrostatic transmission. It is rotated by the input shaft and contains the pistons that pump oil to the hydraulic motor on the other end of the transmission.

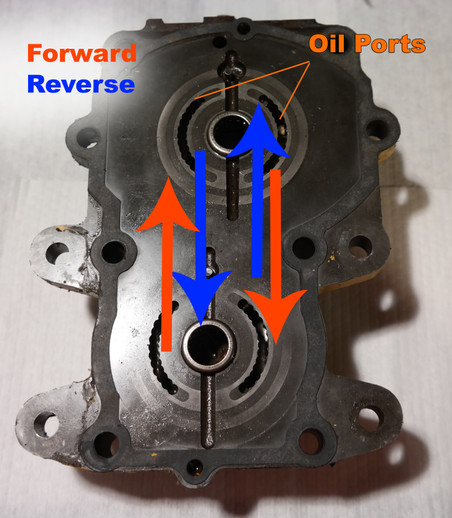

Oil Passageways

The passageways are hollow sections in the case that connect the Piston Pump to the Piston Motor.

Pressure Relief Valves

The pressure relief valves offer an alternative path for oil to flow when the oil pressure reaches a predetermined amount. The pressure relief valve contains a spring that holds a poppet in place to prevent oil from flowing through it. When the oil pressure is able to overcome the spring pressure, the valve opens up allowing oil to pass through it. The Sundstrand Transmission has a charge relief valve, and in some cases has an implement relief valve built into it.

Axial Piston Motor

This motor is what drives the output shaft as a result of oil flowing through it.

Swash Plate

The swash plate changes the displacement of the piston pump. It does this by changing angle in relation to the pistons. This allows the pistons in the pump to pump more oil, less oil, and change direction. The greater the angle of the swash plate, the longer the pistons stroke which pumps a higher volume of oil to the motor. The higher the volume the faster the motor goes. When the swash plate is perfectly parallel to the pistons, there is no pumping action. The entire cylinder block just rotates with the input shaft. With no pumping action, the transmission is in neutral. When the swash plate is tilted in the other direction, the pistons rotate backwards pumping oil in reverse, causing the motor to rotate in the opposite direction.

Check Valves

Check valves keeps oil in the closed circuit loop between the pump and motor. They can be disengaged either automatically or manually to allow oil pressure to escape so the tractor can be pushed.

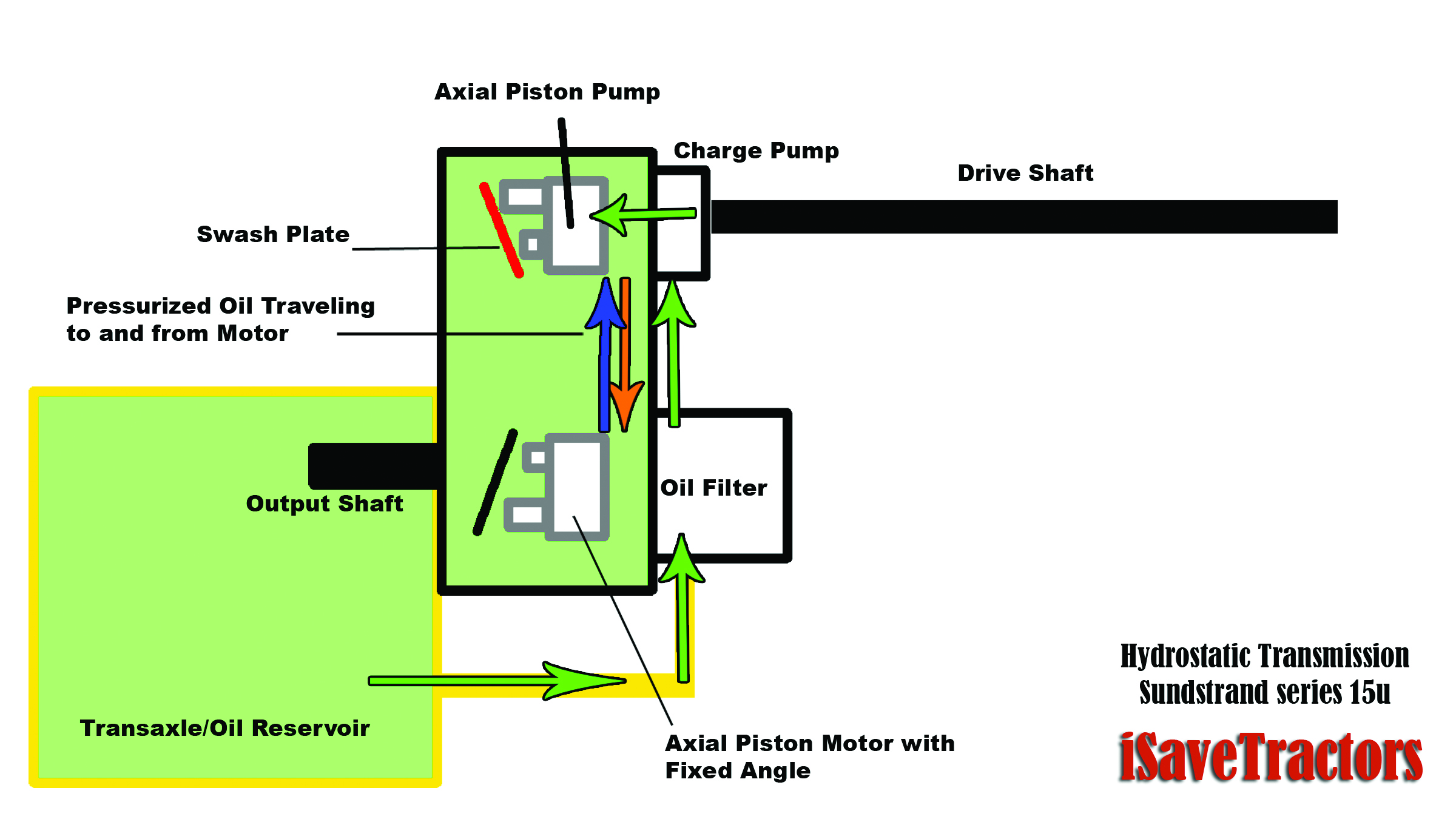

Axial Piston Pump Charge Pump Swash Plate

Now that we know how a hydrostatic transmission uses the properties of oil to create power, and what each major component of the transmission does, let’s follow the path of oil and examine how it all works together. (See illustration)

The oil begins in the reservoir which is the rear differential case on the Cub Cadet Garden Tractor. As the engine runs it rotates the drive shaft. The drive shaft is connected to the input shaft which turns both the charge pump and the axial piston pump. The charge pump draws oil up through the oil filter, and into the transmission case. Oil flows into the case, and into the closed circuit oil passageways.

As the operator moves the transmission control lever, the swash plate changes angle and causes the pistons to move in and out of the piston cylinder as it rotates. The reciprocating motion of the pistons causes oil to circulate through the oil passageways and into the axial piston motor. Since the motor is set against a fixed angle, the pistons cause the motor to rotate as it pushes oil back to the pump. The motor is connected to the output shaft that turns a large bull gear in the differential and power is transferred to the rear wheels.

I hope this article helps you understand the inner workings of your Cub Cadet’s hydrostatic transmission. With this knowledge and understanding we can continue to keep our beloved tractors in excellent working condition for another generation of small tractor enthusiasts.

Thank you for saving the tractors,

- Norman, iSaveTractors

Recent Posts

-

A Letter From the Owner of iSaveTractors

Dear Friends and Fellow Tractor Enthusiasts, After over a decade of serving the vintage small engine …Jun 5th 2025 -

Rebuild your Old Kohler K Series Engine vs Buying New

Why Rebuilding Your Old Kohler K-Series Engine Beats Buying a New Mower or Engine In today’s t …May 13th 2025 -

iSaveTractors vs Cheap Parts from Amazon

Why iSaveTractors Parts Outshine the Cheap Alternatives on Amazon When it comes to restoring and mai …May 12th 2025