Carburetors. How do they work? Part 1

The carburetor is the doorway into your engine. It's primary function is to bring fuel and air into your engine to create combustion.

An engine requires 14.7 parts of air per 1 part of fuel to create an ideal combustion scenario. This ratio is called the "stoichiometric ratio."

A carburetor accomplishes its goal with a simple design utilizing only physics and atmospheric pressure.

Here is how it works:

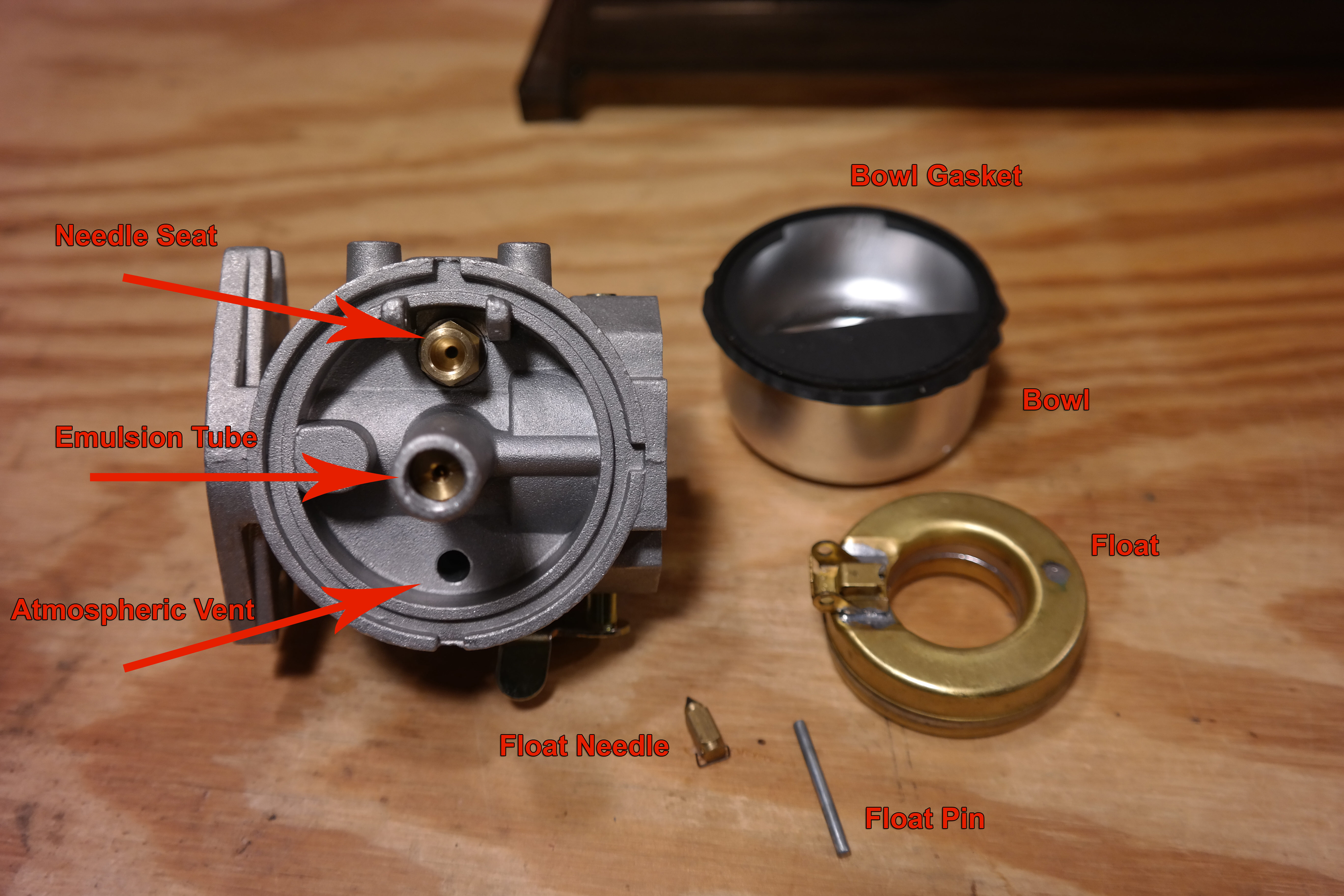

As your engine's piston moves downward on the intake stroke, a low pressure is created in the combustion chamber. This low pressure pulls air through the air filter and into the carburetor throat. As air passes through the venturi the velocity of the moving air speeds up and in this area of low pressure, fuel is pulled from the carburetor bowl, through the emulsion tube, and into the venturi where it is atomized by the fast moving air.

Together the fuel and air mixture continue to travel past the intake valve and into the combustion chamber.

On the compression stroke the piston further compresses the air/fuel mixture creating an ideal scenario for combustion.

Just before your piston reaches Top Dead Center the spark plug ignites and the compressed air fuel mixture turns into a steady burn of energy.

Carburetor Design Features:

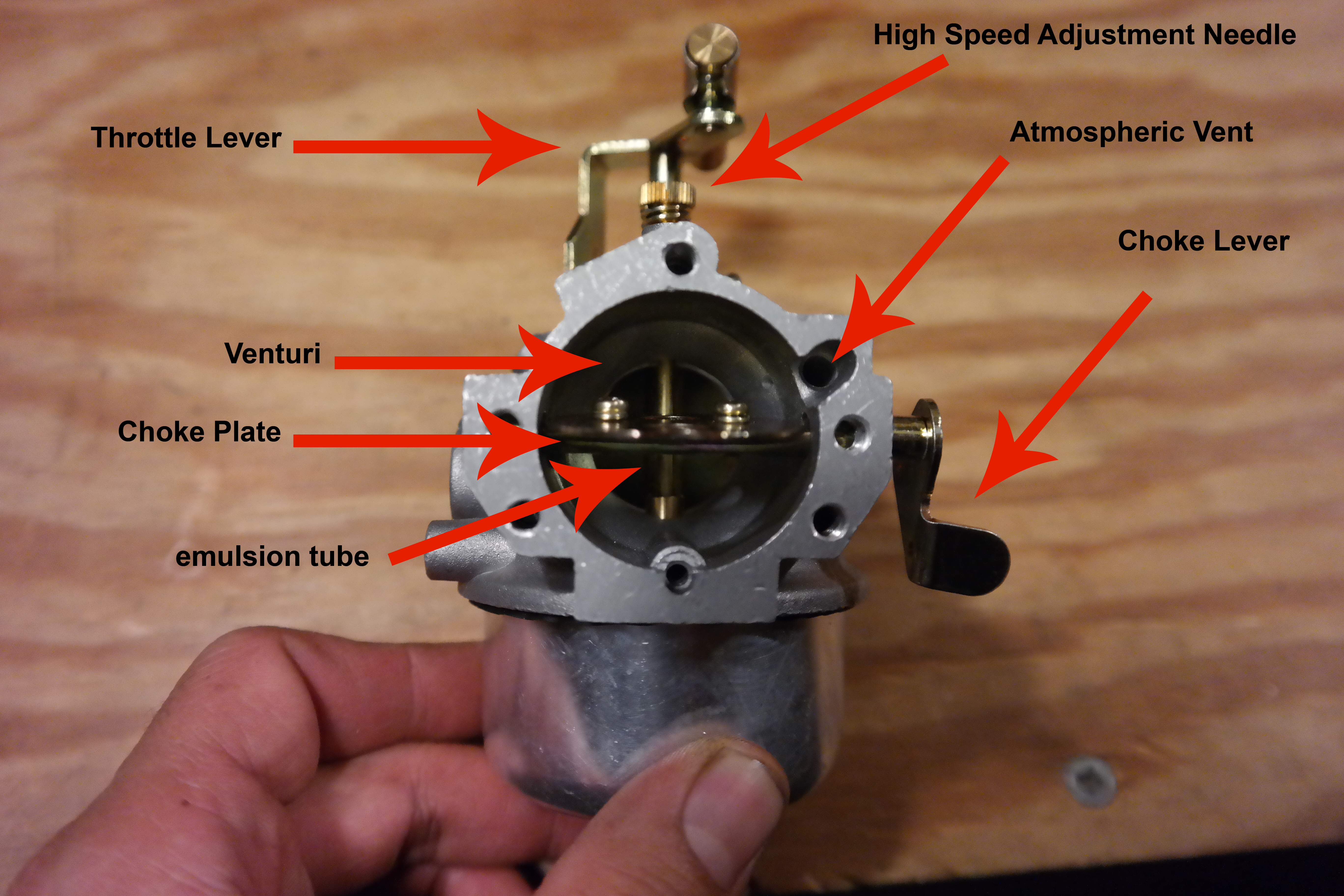

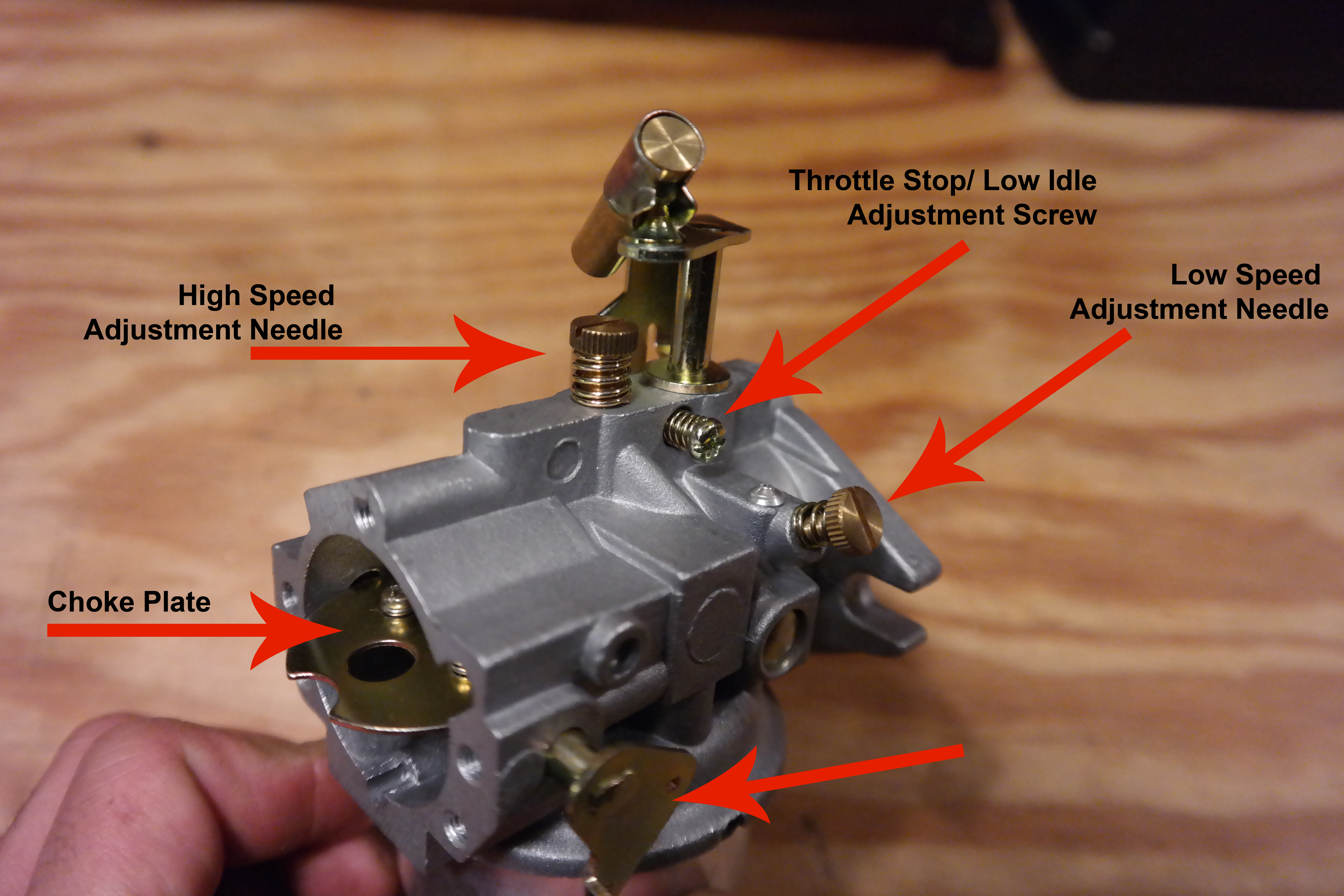

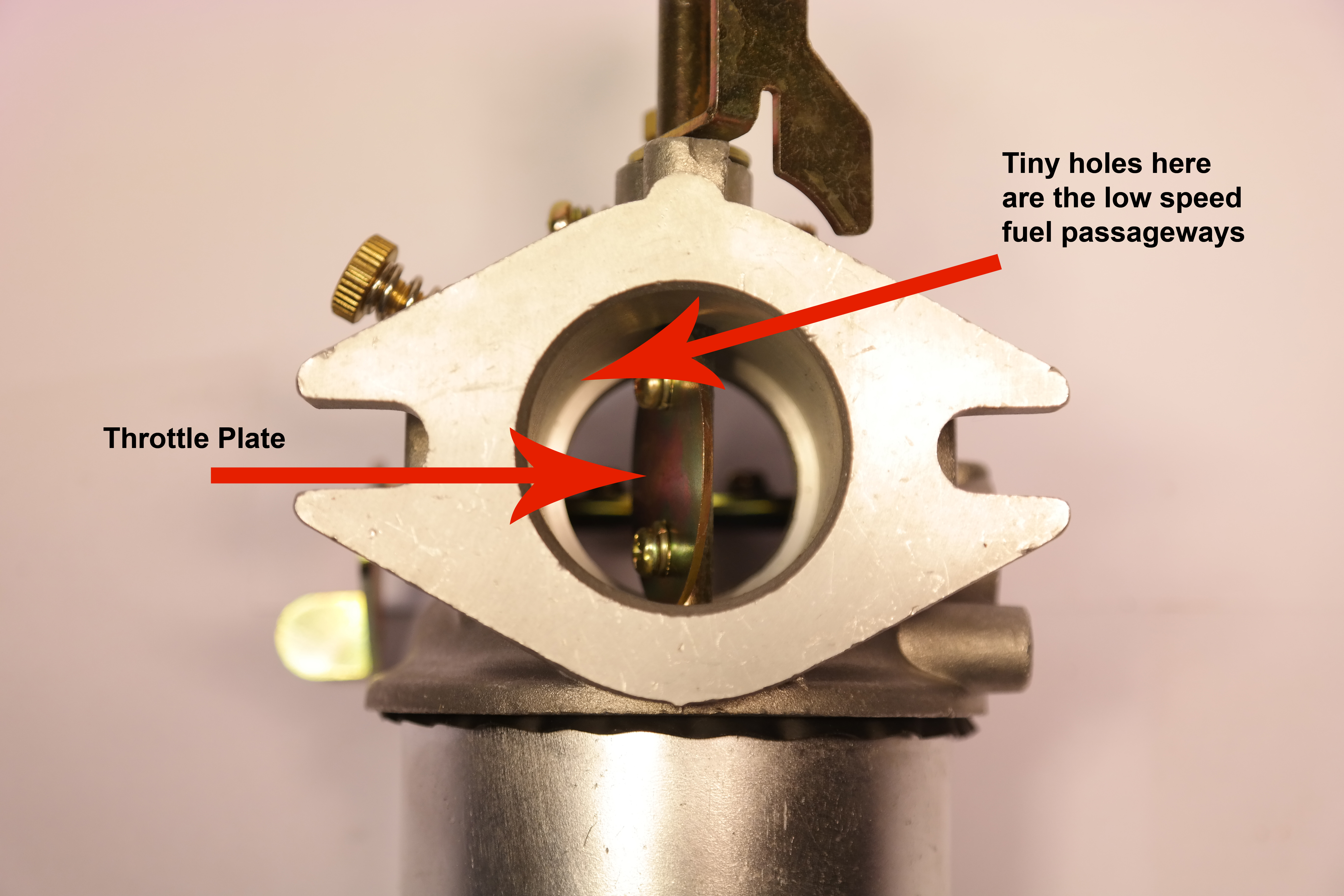

The main components in your carburetor are:

- Choke Plate

- Throttle Plate

- Throttle Stop

- Main Jet

- Low Speed Jet

- Emulsion Tube

- Float

- Float Pin

- Inlet Needle

- Needle Seat

- Atmospheric vent

- Idle passageways

- Gaskets

The images below are of a Kohler #30 Style Carburetor found in Kohler K Series Engines K321 and K341.

In Part 2, we will explain the function of each part in the carburetor.

Thank you for saving the tractors!

Recent Posts

-

Engine Science: Rewind Your Small Tractor Engine Stator - Charging System Repair

Engine Science: How to Rewind Your Statorby Norman Ng, Founder of iSaveTractorsYour engine’s stator …Sep 10th 2020 -

Engine Science: The Digital Multi-Meter

The ability to detect, observe, and measure electricity is crucial when trying to understand how a …May 7th 2019 -

5 Common Small Engine Rebuilding Mistakes

The engine is the heart of your garden tractor. When performing heart surgery on your tractor, be aw …Jan 4th 2019