The Briggs and Stratton Flo Jet Carburetor

Engine Science: The Briggs and Stratton Flo Jet Carburetor

Carburetors typically come in one of three orientations: Side Draft, Down Draft, and Up Draft. These refer to the how air flows through the carburetor. The different orientations offer advantages in the position they mount to the engine.

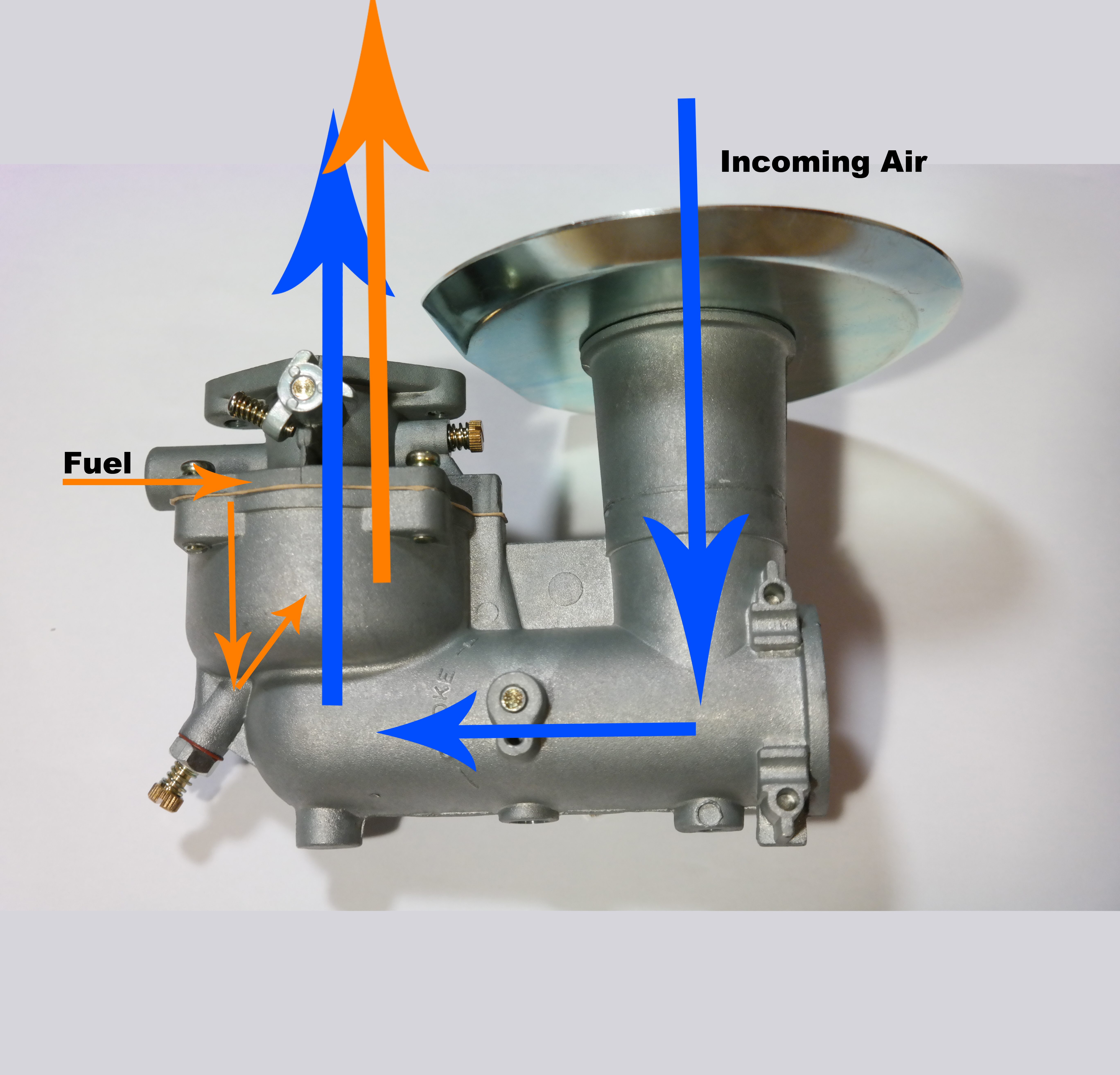

The earliest design was the updraft carburetor. This updraft design allowed the carburetor to sit lower beside the engine to aid in gravity feeding fuel. Air enters the carburetor and is redirected upward as it passes through the venturi.

The side draft carburetor has air flowing sideways as it passes through the venturi.

The downdraft carburetor has air flow downward through the venturi. The downdraft carburetor allows it to be positioned above the engine and offers space saving advantages over the updraft and side draft designs. Twin cylinder engines frequently used down draft carburetors.

The Briggs and Stratton Cast Iron Engines use the Flo Jet Carburetor which is an updraft design. The two most common Flo Jet carburetors are the Medium and Large 2 piece Flo Jets. They are commonly referred to as a “3 Bolt Carb “for the medium Flo Jet and a “4 Bolt Carb” for the Large Flo Jet. The Flo Jet carburetors have some unique characteristics that lead to end user problems and confusion on how to solve them.

This article is to help you understand how the Flo Jet carburetor works and how to solve some of the common issues associated with them.

Basics of a Carburetor:

A carburetor utilizes air pressure differentials to move an air and fuel mixture through it and into the engine. Using Bernoulli’s principle we are able to achieve a 14.7:1 air fuel ratio for optimum engine performance.

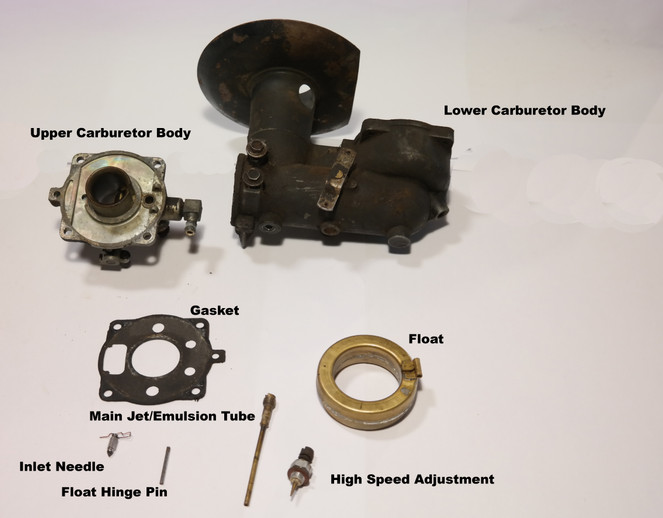

The Flo Jet consists of the following primary Components:

- 1.Upper Half Body

- 2.Lower Half Body

- 3.Throttle Plate

- 4.Choke Plate

- 5.Main Speed Adjustment Needle

- 6.Low Speed Adjustment Needle

- 7.Emulsion Tub/Main Jet

- 8.Float

- 9.Inlet Needle

- 10.Inlet Seat

- 11.Gasket

How

the Flo Jet Carburetor Works:

How

the Flo Jet Carburetor Works:

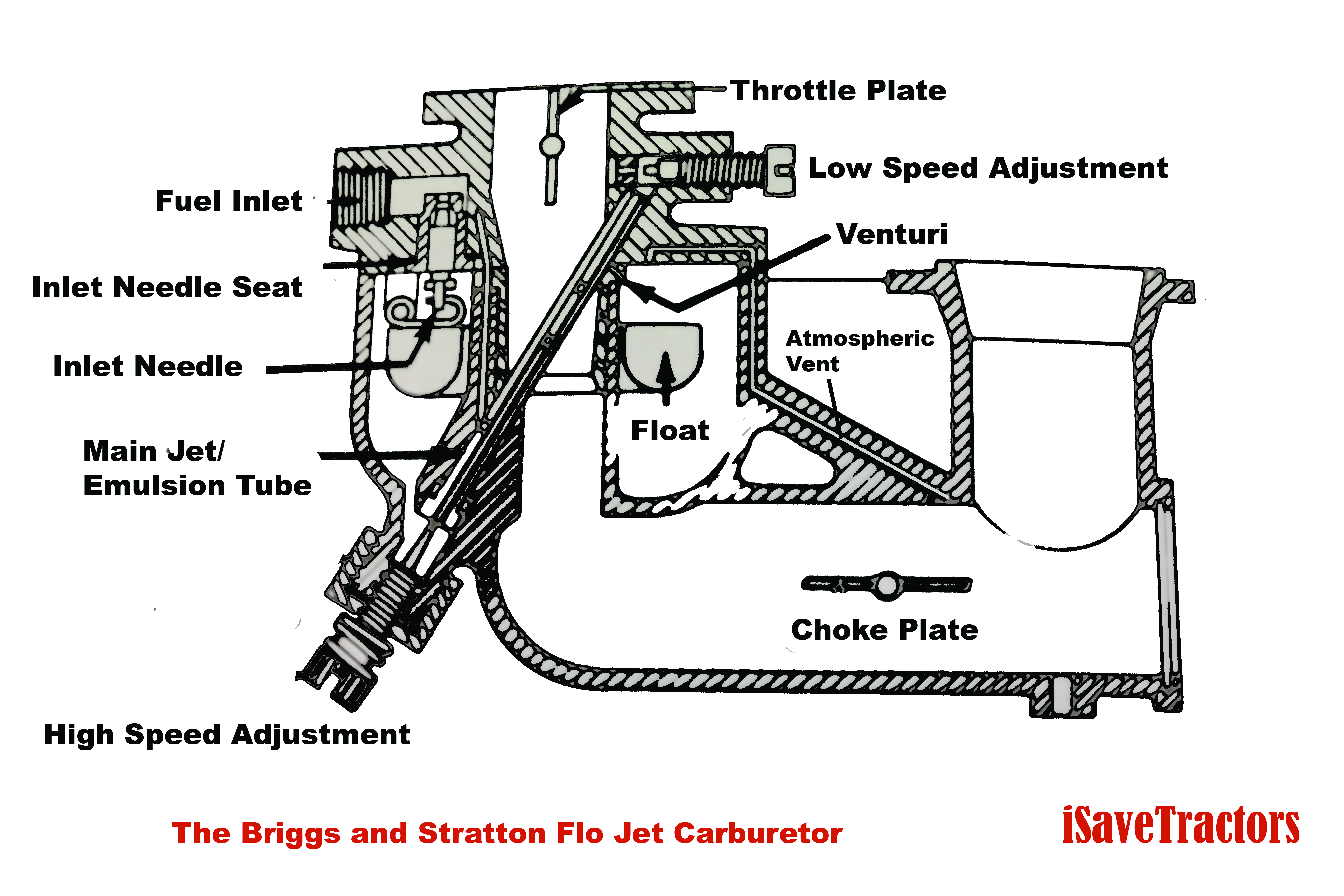

Fuel enters your carburetor through the fuel inlet and fills the fuel bowl. The atmospheric vent allows atmospheric pressure into the fuel bowl as well.

As the piston in your engine moves downward it creates a vacuum which draws in air through the intake end of the carburetor. As the air travels through the venturi, the air’s pressure drops, and fuel is drawn down from the fuel bowl, and then back up through the main jet and emulsion tube. The low pressure air mixes with and atomizes the fuel. This air/fuel mixture continues through the intake valve and into your combustion chamber.

This works like every other carburetor but the Flo Jet design has two unique characteristics that plague many owners:

- -Emulsion Tube/Main Jet sits below the fuel bowl.

- -The atmospheric Vent runs from the upper half of the carburetor to the lower half of the carburetor

Common issues with Flo Jet Carburetors:

The problem most users encounter is a leak from inside the carburetor. The leaks seem mysterious and unsolvable to many. The two unique characteristics mentioned earlier are where the leaks occur. Let’s examine why:

The Emulsion Tube/Main Jet sits below the fuel bowl. This results in the emulsion tube and main jet to constantly have fuel pressure against it. The original design relies on the mating surfaces between the carburetor body and the main jet/emulsion tube to be perfect in order to provide a seal between each other. As corrosion and age set into your carburetor, this seal is often compromised. Since fuel is always being pulled down toward the main jet area, fuel will continuously leak out causing an overly rich air/fuel mixture, and loss of fuel.

The atmospheric vent is divided by the two halves of the carburetor. As a result fuel can leak in between the gasket and flow into the atmospheric vent and down into the carburetor. This also causes loss of fuel and a rich air/fuel mixture. The fuel level needs to be slightly below the bottom half of the carburetor to prevent this. Warping of the carburetor halves can also create an easier path for fuel to leak into the atmospheric vent.

Solutions to the Flo Jet Leak:

Briggs and Stratton recommends using a lapping compound to polish the surface of the carburetor body and the shoulder of the emulsion tube to restore the sealing surface. I have found simply installing a neoprene o-ring on the emulsion tube provides a longer lasting and more reliable seal.

To solve the leak into the atmospheric vent make sure your float level is adjusted perfectly. The float should be perfectly parallel to the upper carburetor body or sit slightly lower than level. This keeps fuel below where the two halves of the atmospheric vent meet. Also make sure your carburetor halves are not warped when the bolts are tightened down. If there is a visible gap between the two halves of the carburetor at the atmospheric vent; sand down the two halves until the gap is gone.

I hope this helps you solve your Flo Jet Carburetor Problems.

Thank you for saving the tractors!

- -Norman Ng, iSaveTractors.com

Recent Posts

-

Engine Science: Rewind Your Small Tractor Engine Stator - Charging System Repair

Engine Science: How to Rewind Your Statorby Norman Ng, Founder of iSaveTractorsYour engine’s stator …Sep 10th 2020 -

Engine Science: The Digital Multi-Meter

The ability to detect, observe, and measure electricity is crucial when trying to understand how a …May 7th 2019 -

5 Common Small Engine Rebuilding Mistakes

The engine is the heart of your garden tractor. When performing heart surgery on your tractor, be aw …Jan 4th 2019